Wind Energy – FWIV

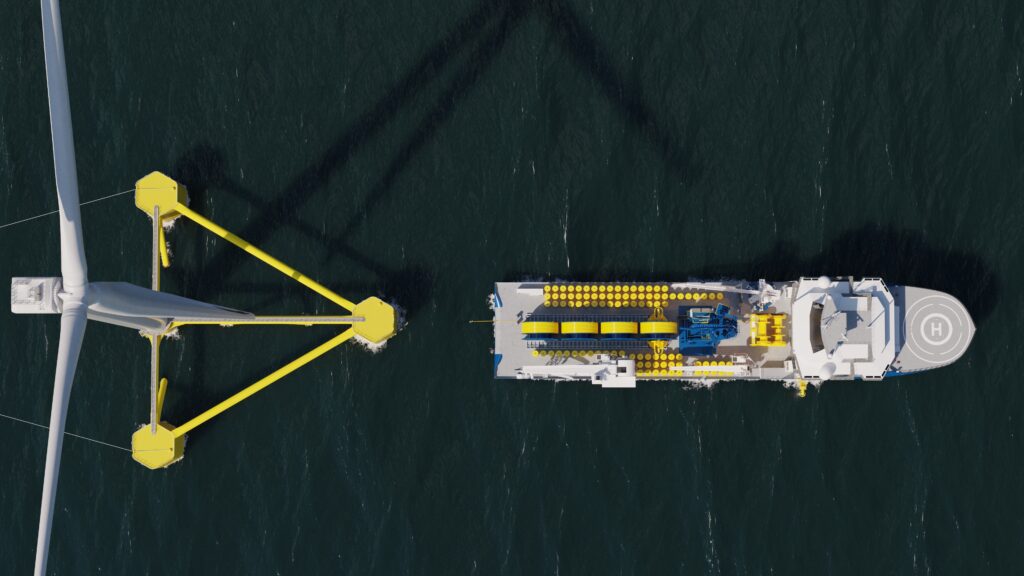

NOV has launched the Enhydra Floating Wind Installation Vessel (FWIV) concept to facilitate the commercialization of floating wind.

Since floating wind farms are further offshore, in deeper waters, and in harsher environments, new and robust installation strategies are essential.

This versatile vessel concept is designed to operate safely, effectively, and longer in the harshest environments and deep waters. Its modular and integrated design enables the installation and hookup of various floater types, mooring systems, and dynamic cables, streamlining complex offshore operations.

Each floating wind farm demands a tailored approach to its geographic and environmental conditions. Combining mooring and dynamic cable installation and hookup capabilities boosts the Enhydra FWIV’s role as a key asset for commercial-scale floating wind farms.

This cutting-edge FWIV concept results from collaborations that span not only NOV’s Marine and Construction business unit but also input from offshore wind developers, EPIC contractors, and specialist original equipment manufacturers.

The GustoMSC vessel design offers a flexible deck layout- and specific provisions for mission equipment integration, including electric subsea cranes from Lifting and Handling and Remacut cable-lay systems.

The FWIV is the next design in GustoMSC’s Enhydra offshore wind support vessel series. The series design characteristics resemble the sea otter’s (Enhydra) unique physical and behavioral features. This marine mammal uses its streamlined body design to perform dives to the seafloor efficiently and adapt its lung capacity to float effectively on the surface.

NOV believes the nascent floating wind market presents one of the greatest renewable energy resource opportunities of the next decade. Many regions around the world including Europe, Asia and the Americas including the US – particularly the West Coast – offer vast potential. By ensuring compliance with all relevant regional requirements, including the US Jones Act, NOV has expanded the potential scope of the local supply chain for the Enhydra FWIV, making it possible to build the vessel at proficient shipyards across the globe.