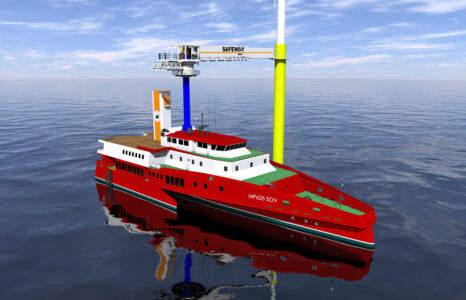

To meet the future requirements of the offshore wind industry in the overall project logistics and turbine related O&M activities, Spanish engineering company Marcelo Penna Engineering and Safeway, the Dutch specialist in the design and manufacture of offshore transfer equipment, have joined forces to design an intelligent Service Operation Vessel with a very high focus on crew comfort, safety, reliability and workability in combination with lowering costs. The outcome of this collaboration is the battery-hybrid MP625 SOV combined with the recently introduced Gannet 3D motion-compensated offshore access system.

Artist impression of the MP625 SOV. If required, the vessel can be equipped with a helideck.

Offshore wind farms have to reduce the Levelized Cost of Energy (LCoE), innovations and new technologies are needed to realize cost reduction. On one hand nowadays concession auctions, sometimes even zero-subsidy in modern wind farms results in an aggressively need to minimize their life-of-field costs. Moreover, on the other hand, the older and less-efficient offshore wind farms feel even greater pressure to manage costs. And this is exactly what is steering wind majors away from existing highly cost SOV vessels towards revolutionary designs, such as the futureproof MP625 SOV of Marcelo Penna Engineering combined with the Gannet, Safeway’s most advanced type of access system, allowing technicians to move safely between vessel and offshore wind turbines. A big advantage of this cost-saving engineering solution is that the SOV can stay on a wind farm, even in the roughest sea conditions. And thanks to the unique features of the 3D motion compensated gangway, the floating duo is able to offer a degree of safety, flexibility and effectiveness previously unseen in the international offshore gangway industry.

Innovation

“For both our companies innovation was the key driver behind this partnership. It is therefore obvious that our common goal throughout the engineering process was to come up with a high-quality design and cutting-edge technology that would minimize construction and maintenance costs, maximize operational efficiency at sea and reduce any unplanned downtime,” explained Marcelo Penna, CEO of Marcelo Penna Engineering in an exclusive interview with Ocean Energy Resources.

“Our multidisciplinary teams were in constant contact. This intensive R&D cooperation worked quite well. After several months of hard work, an extensive tank test campaign could be carried out, resulting in an efficient hull shape that is offering the best compromise between resistance, seakeeping and stability. This really is a significant step up. And we are confident that the MP625 SOV and Safeway’s Gannet gangway will become a popular combination in the demanding and fast-growing SOV market.”

Workability

This trimaran hull feature gains extra value in case of high seas, as the reduction of speed is almost zero compared to a calm sea state. The design allows for up to 21 kts of max speed while providing full comfort for personnel and cargo transfers with up to 3,5m waves, compared to the industry norm of Hs 2.5m. Equipped with an A-frame at the boom tip of the Safeway Gannet, the operator can also switch from People Transfer Mode to Cargo Transfer Mode, activating a lift capacity between 1,000 and 2,000 kg remotely with the touch of a button. In addition to this personnel and cargo transfer, the Safeway Gannet will also be able to carry automated trolleys through the gangway of the type that many offshore operators like to use to take equipment and tools across to a turbine. Various simulation tests have shown that this newly designed DP-2 SOV, combined with the distinctive Safeway Gannet gangway parameters, has proven unrivalled workability throughout the year.

Market requirements

“Our Gannet 3D motion-compensated access system was developed in response to evolving requirements for fast, safe and efficient walk-to-work systems such as those being sought by Equinor and its partners for the massive offshore wind farms they plan to build on Dogger Bank,” added Wijnand van Aalst, CEO of Safeway. “Earlier this year Equinor has issued a tender for a new class SOV, which is quite demanding for a number of reasons. The first is that the access system installed on the vessel will need to be able to connect and transfer personnel and equipment in a significant wave height of 3.5 m Hs. The second is that the SOV will be somewhat smaller than those built to date for services in the North Sea. Equinor wants to do transfers with a high landing point from what will be a very compact vessel.”

Hover mode of a Safeway Seagull gangway.

Hover mode

Van Aalst continued: “Safeway’s Gannet type of gangway meets the requirements of Equinor in every respect, so we really believe that she can provide a very high level of workability. Our confidence is based on some of the unique features of Safeway’s motion-compensated series of gangways. These include its well-known ‘zero impact bumpering’ or ‘hover mode’, and its roll compensation capability. Hover mode means that the gangway does not physically push against the landing point on a turbine or offshore structure. In practice, it means that you can ‘land’ the gangway with the vessel in any position. This is a big advantage because it means that you can select the best heading for the vessel towards the waves, whatever the conditions, and maximise the workability. Whether you are transferring people to a bottom-fixed or floating turbine, it always enables the vessel to place the gangway further over the target structure, which eliminates the gap that you sometimes get with a gangway that is trying to connect directly to a specific landing point.”

Optional on board the MP625 SOV is that the gangway operator and DP officer can operate side-by-side in the wheelhouse during a landing. As autonomous operations of the Safeway Gannet are also foreseen the tasks of the gangway operator will be minimised.

Safeway’s Gannet type of gangway.

Roll compensation

Roll compensation has become an increasingly important capability as the height above sea level at which technicians need to be transferred, has grown over the last few years. Wijnand van Aalst added: “Any vessel, however well designed, will experience some rolling motion, but its effect grows as the height at which transfers take place, increases. Much existing equipment was designed with a transfer height of 18-21m in mind. But the fact that wind turbines have grown and more and more wind farms are being built in areas with significant variation in conditions and in water depth, has meant that gangways need be able to land at least 25-28m above sea level to transfer personnel safely and quickly. At that kind of height, even a small amount of vessel roll, can make a lot of difference.”

Dayroom on board the MP625 SOV.

To date, according to Wijnand, other gangways have compensated this with a too high telescoping speed. Even speeds of up to 4m per second or 15 km/hr have been used. This, however, will make users hesitant, because they feel unsafe and in fact they are right, these speeds are too high. “Within Safeway we limit the telescoping speed up to 7 km/hr or 2m/s. With Safeway’s unique and patented roll compensation capability in Safeway Gannet, we can reduce telescoping speed significantly, remaining with very high workability. By doing so we make crossing a gangway as safe as possible, combining reduced motions with a fully enclosed, protected walkway, so the experience is as comfortable as walking onto an aircraft.” On top of that Van Aalst claimed that compared to a system without roll compensation, transfers can be completed 25-30% more quickly.

Compact vessel

“To meet the operators’ desire to build smaller ships, we managed to design this SOV with a length of only 64m,” continued Marcelo Penna. “Our MP625 is around 20m smaller than SOVs built to date. In addition, the vessel will be equipped with three of the strongest MAN diesel engines each of them being coupled with two electric engines offering a hybrid solution and a total output power of 4.4 MW. We also decided to equip the vessel with lithium batteries, making her capable of remaining in DP for up to 12 hours in silent mode. All these solutions imply a very low fuel consumption. On top of that, the reduced size of the vessel and easiness of construction allows us to reach much lower construction budgets, implying severely reduced OPEX and CAPEX compared to current mono hulls.”

Stability and comfort

One of the main advantages of the MP625 is that the vessel can largely extend its weather window thanks to its stability and comfort. Where big mono hulls can’t keep their DP with the result that technician transfer becomes dangerous or even impracticable, the MP625 SOV will stay in place with up to Hs=4m waves and keep the transfer flow as determined in a workability study made by Safeway. “This is mainly achieved because motions and accelerations, the two main causes of seasickness, are almost null due to the design of our vessel,” explained Marcelo Penna.

“In this respect it is important to point out that the MP625 does not require gyro of fin stabilisers, implying largely reduced installation and maintenance costs. On the other hand, comfort, live aboard and safety are aspects we have accurately studied anyway. The vessel is equipped with single cabins for technicians designed to the latest comfort standards, a multimedia room, leisure and relaxation areas as well as a fully-equipped fitness room, warehouse and workshop. In case of the Equinor tender the SOV is the homely offshore base for up to 20 technicians plus a nautical crew, but this number can be scaled up to 30 technicians.”

By offering the international offshore wind market this intelligent and futureproof SOV/access system concept easily exceeding the performance of comparable vessels with different gangways, Marcelo Penna Engineering and Safeway aim to support wind farm developers in the realisation of projects that contribute to the transition to renewable energy.