Wind Energy – TouchWind

We4Ce, a Dutch rotor blade designer, has designed 10 rotor blade sets for Dutch wind turbine startup TouchWind for testing on its floating TW6 turbine.

This turbine is a self-tilting, one-piece rotor design that breaks from conventional three-blade models.

Engineered to withstand wind speeds of up to 250 km/h—the highest wind class in wind industry standards—the future commercial version is expected to cost significantly less than traditional turbines while delivering higher energy yields.

Responsible for the blade design, We4Ce partnered with Dutch mould specialist Kleizen to produce both the moulds and blades. TouchWind, backed by its main shareholder, Japan-based Mitsui O.S.K. Lines (MOL), contracted We4Ce as lead partner for the blades.

The delivery of the blades marks the next prototype phase of TouchWind’s innovative tilting, one-piece rotor wind turbine. Featuring a six-meter-diameter rotor designed for efficient energy capture, the 12 kW turbines will be tested onshore and offshore.

The turbines will be placed close to one another to validate the high energy density previously demonstrated in wind tunnel tests. Currently being assembled in Eindhoven, the wind turbine will start testing in the summer.

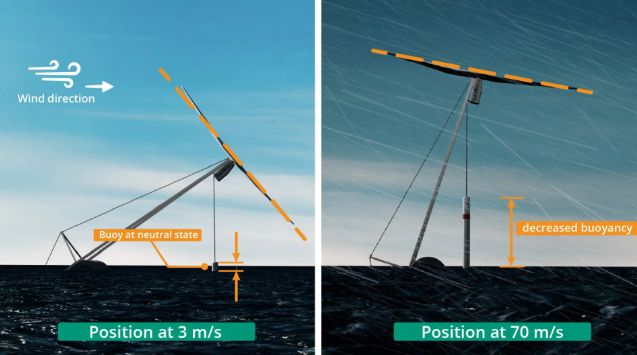

The turbine functions similarly to a kite: instead of pushing against the wind like traditional turbines, it ‘lifts itself’ with the wind, using aerodynamic lift to stay stable and to regulate the power. This configuration allows the blade to harness strong winds more efficiently while reducing stress on the structure.

TouchWind’s design not only aims to reduce wind interference between wind turbines, a common issue in large wind farms, but also to improve overall wind farm power generation efficiency.

The unique design with lifting rotor reduces the overall weight of both the wind turbine and its floating platform, contributing to simpler and more cost-effective deployment.