Wind Energy – Innovation Maintenance

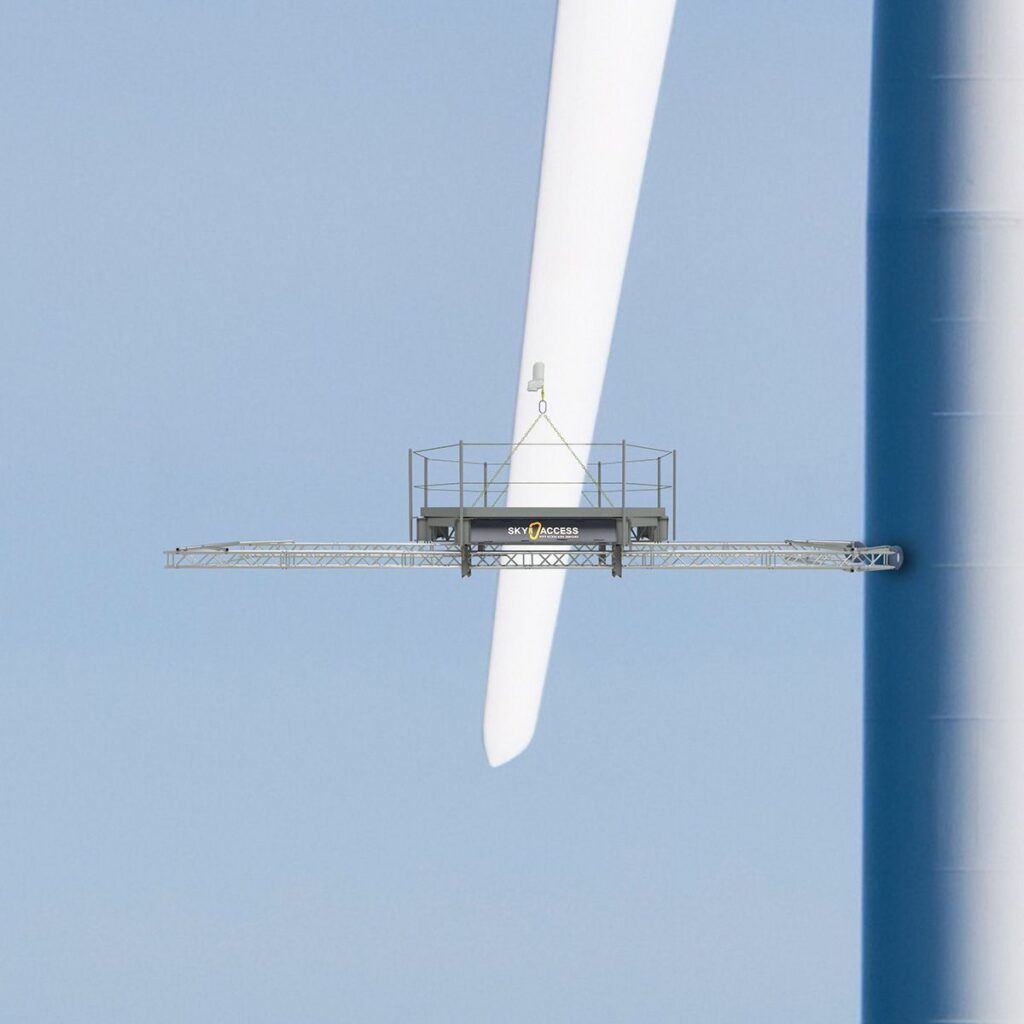

Sky Access, based in Roosendaal, the Netherlands, introduces the revolutionary SkyDeck Blade Platform to simplify the maintenance of offshore wind turbines.

Designed, developed and patented by Sky Access, the game-changing SkyDeck Blade Platform, is ideally suited for wind turbine repairs in offshore environments.

Lengthy rope access blade repairs can be simplified and shortened, reducing turbine downtime. Even the replacement of damaged blades by offshore lifting vessels is no longer necessary. This translates directly to huge cost savings.

When rope access inspections and drone photography show that a wind turbine requires multi-day repairs, the SkyDeck Blade Platform is the obvious solution.

Because the work platform is modular, it can be adapted to suit virtually any type of turbine blade. The system has other advantages, such as being easily transported in small packages on a standard crew transfer vessel.

The components are bundled into 250 to 500 kg packages, which takes into account the low lifting capacity of the cranes on the transition pieces.

In a normal day shift, a team of four rope access technicians assembles the work platform. This includes electric winches and their power supply.

In yet another shift, Sky-Access dismantles the work platform.

Sky Access designs, assembles, dismantles, and hires out the platform on a bespoke basis.

This means that the existing rope access contractor uses the platform and carries out the repairs. Sky Access’ turbine blade specialists can also carry out the repairs and or assist other teams.