Fossil energy – Australia

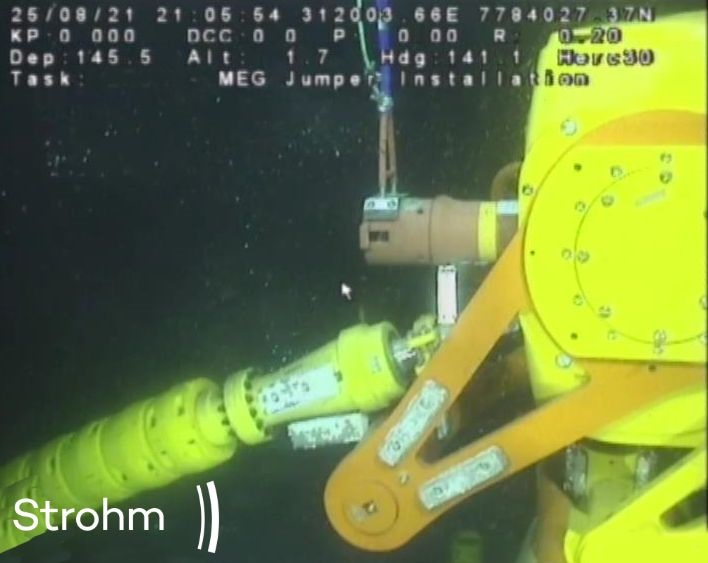

Strohm from the Netherlands is the first company to deploy a Thermoplastic Composite Pipe (TCP) Jumper in Australia, for a Subsea 7 project offshore the North-western shelf.

The TCP Jumper is non-corrosive, lightweight, flexible, spoolable with a small minimum bend radius and can be terminated at any location along the pipe. This provides the end user with project value in lower total installed cost through cost effective transportation, and removing the need for metrology, hence de-risking the project schedule.

Strohm’s TCP solution is 80% lighter in weight compared to its metallic equivalents, leading to improved transportation and installation costs. It is completely impervious to corrosion and has a high collapse resistance, offering a significantly extended service life. TCP’s manufacturing process also has a reduced manufacturing footprint, producing 50% lower CO2 levels compared to carbon steel pipe.

For TCP Jumpers such as those provided for Subsea 7’s project, a particular benefit is the elimination of offshore metrology requirements, leading to a considerable improvement on the cost and schedule risks associated with vessel standby and onshore rigid spool fabrication.

A logical step forward from the single jumper application is the Strohm ‘Jumper on Demand’ concept whereby a long length of pipe is fabricated and stored on a single reel or cradle, ready to be cut and terminated in-country into individual jumpers as required.